Combined Manufacturing Solutions:

Stamping, Machining & Welding

Kolte Pressing Works (KPW) provides a seamless, end to end manufacturing solution by integrating our core strengths Precision Stamping, CNC Machining, and Advanced Welding under one roof. By delivering "Ready-to-Use" combined products, we help our global clients simplify their supply chains, reduce procurement costs, and ensure consistent quality across multi process components.

Our Integrated Manufacturing Capabilities

Our facility in Bhosari, Pune, is engineered to handle complex sub-assemblies that require the marriage of different manufacturing disciplines:

- Precision Stamping & Forming: Utilizing presses from 20T to 500T to create the structural base of the component.

- High-Accuracy Machining Adding critical features, threads, and tight-tolerance finishes using VMC and CNC technology.

-

Expert

Welding Services

Our certified welders and robotic systems specialize

in :

- MIG (Metal Inert Gas) Welding: For high-strength structural bonds.

- TIG (Tungsten Inert Gas) Welding: For precision and aesthetic welds.

- Robotic Welding: To ensure repeatability and speed for high-volume automotive orders.

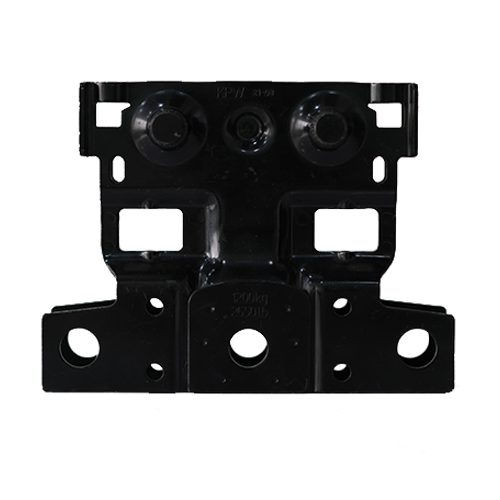

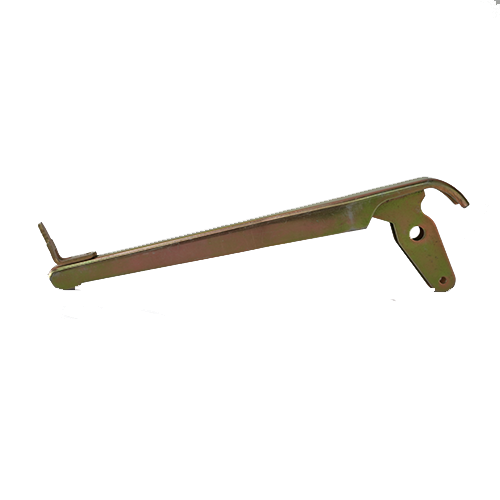

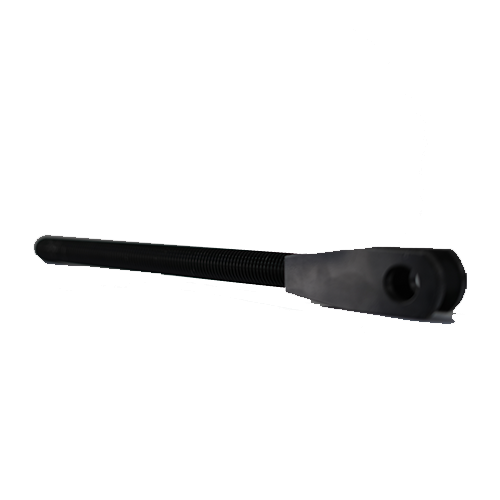

Featured Combined Products & Sub-Assemblies

Below is a showcase of our specialized integrated components designed for durability and performance:

- Piston Rod & Welded Yoke Assemblies: Precision-turned rods integrated with heavy-duty welded yokes for hydraulic applications.

- Light Crane Trolleys: Complex assemblies involving stamped frames, machined wheels, and structural welding.

- Suspension Brackets: High-strength automotive brackets requiring multi-stage pressing and precision welding.

- Shell Cover Fan Motors: Integrated solutions for the electrical and HVAC industries

- PHEM & Hand Release Levers: Ergonomic and functional assemblies for material handling equipment.

- Custom Brackets & Hangers: Multi-process parts optimized for load-bearing capacity and corrosion resistance.

The KPW Advantage: Why Choose Combined Products?

- Single-Source Accountability From raw material to final assembly, KPW owns the entire quality process.

- Reduced Lead Times Eliminating the need to move parts between multiple vendors significantly speeds up production.

- Cost Efficiency Integrated manufacturing reduces logistics costs and minimizes material waste.

- Global Compliance Every assembly is tested to meet international standards, ensuring 100% reliability for our 80% export market in the USA and Europe.