Machined Parts Manufacturer in India

KPW stands as a premier machined parts manufacturer in India, delivering precision-engineered components that power critical applications across automotive, construction equipment, oil and gas, and general engineering sectors. Since our establishment in 1996, our unwavering commitment to excellence has positioned us as a trusted partner for businesses seeking high-quality CNC machined parts that meet international standards.

With state-of-the-art CNC machining centers and over two decades of manufacturing expertise, we transform raw materials into precision components that meet the most demanding specifications. Our machined products reflect the perfect balance of advanced technology, skilled craftsmanship, and rigorous quality control processes that ensure every component leaving our facility exceeds customer expectations.

Precision CNC Machining Capabilities

Our advanced manufacturing facility in Pune, Maharashtra, houses cutting-edge CNC machining equipment capable of producing complex geometries with micron-level precision. As a leading provider of CNC machined parts in India, we specialize in multi-axis machining, precision turning, milling, drilling, and grinding operations across a wide range of materials including mild steel, stainless steel, brass, aluminum, and high-tensile alloys.

Our CNC machines handle batch sizes from single prototypes to large-scale production runs, ensuring consistency and reliability in every piece. We serve industries where precision is non-negotiable, including automotive transmission systems, hydraulic assemblies, construction equipment, and industrial machinery. Each component undergoes stringent quality checks using advanced metrology equipment to ensure dimensional accuracy, surface finish requirements, and material specifications are precisely met.

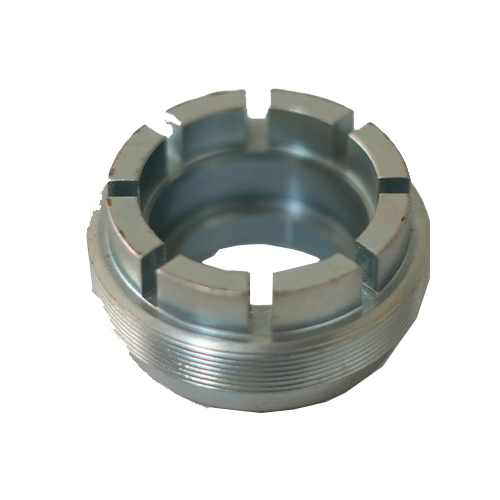

Our machining capabilities enable us to manufacture components with intricate features, precise bore diameters, accurate thread profiles, and superior surface finishes. Whether you require simple turned components or complex multi-feature machined assemblies, our technical expertise and modern equipment ensure optimal results.

Comprehensive Machined Product Range

As a versatile machined parts manufacturer, we produce an extensive range of precision components serving diverse industrial applications:

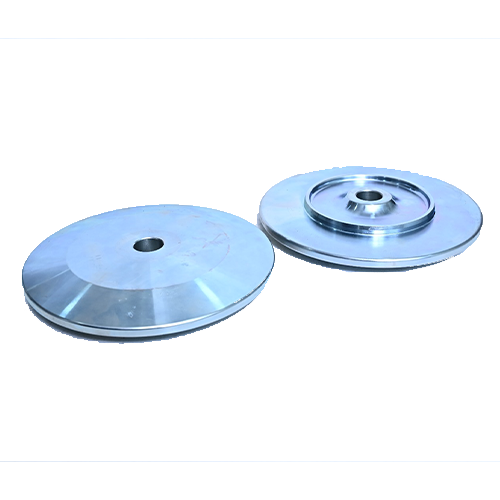

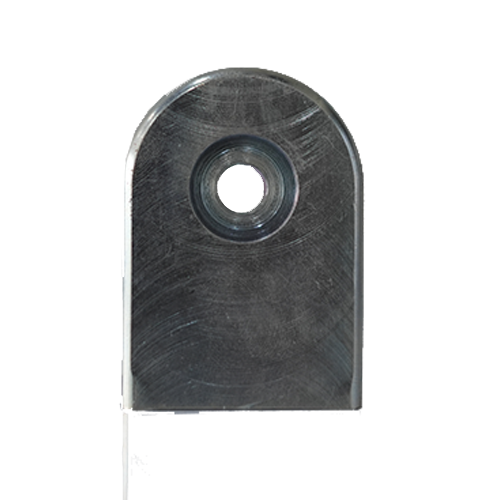

Hydraulic System Components

Our expertise in manufacturing hydraulic covers, pistons, cylinder heads, and related components makes us a preferred supplier for the hydraulic systems industry. These precision-machined parts feature tight tolerances and superior surface finishes critical for leak-proof operation, optimal sealing, and extended service life.

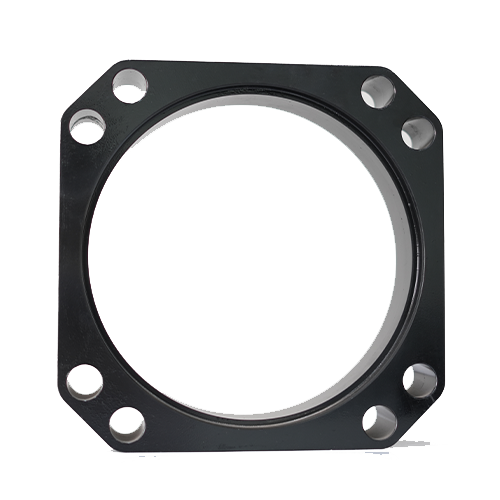

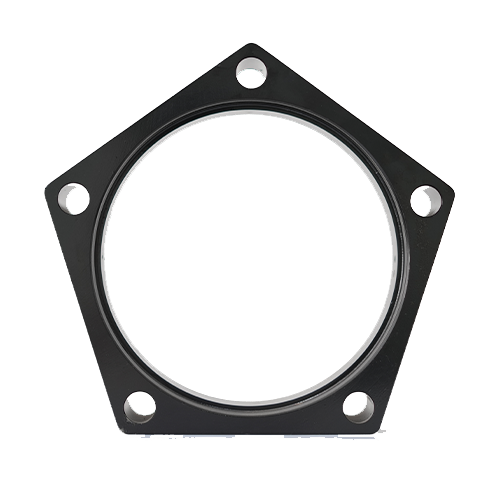

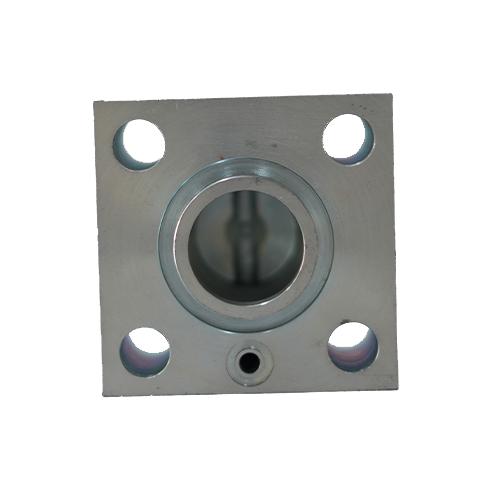

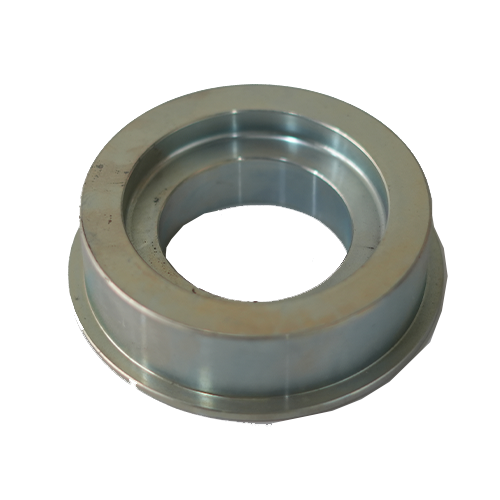

Flanges & Industrial Connectors

Our machined flanges and connectors for oil and gas applications meet industry-specific standards for pressure ratings, material certifications, and dimensional accuracy. Precision bore diameters and accurate bolt patterns ensure reliable, leak-free connections.

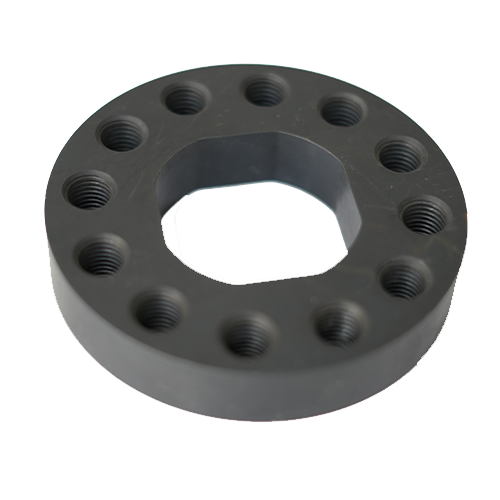

High-Strength Fastening Systems

We manufacture high-tensile tension nuts, adjustment nuts, precision bolts, and specialty fasteners. CNC machining ensures thread accuracy, load-bearing capacity, and compliance with DIN, ISO, and customer specifications.

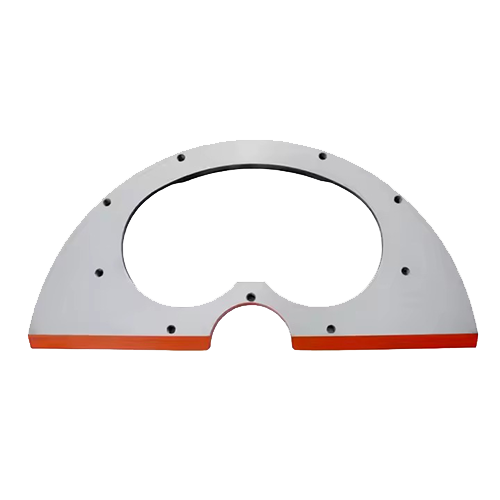

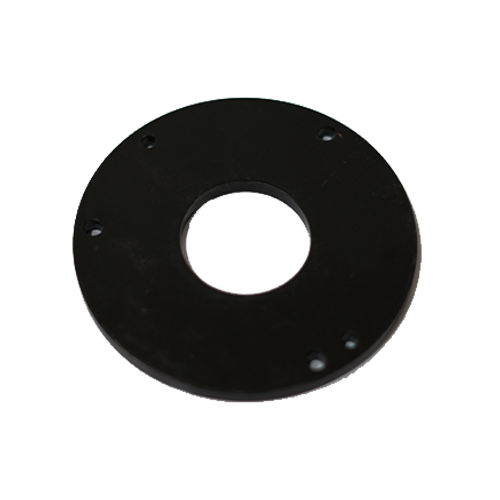

Specialized Components

From friction discs and setting discs to concrete pump rock covers, front plates, clamps, and custom-engineered components, our diverse portfolio highlights our CNC machining versatility across industries.

Bearing & Rotational Components

Pins, bushes, eccentric pins, suspension pins, and piston pins manufactured at our facility demonstrate our ability to handle intricate geometries and stringent tolerances essential for automotive, construction, and industrial machinery applications.

Why Choose KPW as Your Machined Parts Partner

ISO-Certified Manufacturing Excellence

Our ISO 9001:2015 certification underscores our commitment to world-class quality management systems. Every machined component produced at our facility undergoes documented inspection procedures, ensuring complete traceability and strict compliance with customer specifications and international quality standards.

Advanced CNC Technology Investment

We continuously invest in modern CNC machining technology to maintain our competitive edge as a leading machined parts manufacturer in India. Our equipment includes sophisticated multi-axis machining centers, precision CNC lathes, advanced grinding machines, and state-of-the-art inspection equipment capable of verifying tolerances and surface finishes to the highest standards

Material Expertise and Selection

With extensive experience machining various materials including carbon steel, stainless steel grades (304, 316, 410), brass, bronze, aluminum alloys, and high-strength specialty alloys, we provide expert recommendations for optimal material selections based on application requirements, operating conditions, environmental factors, and cost considerations.

Global Quality Standards Compliance

Exporting 80% of our production to customers in the USA and European markets, we consistently adhere to international quality standards. Our quality assurance team performs comprehensive dimensional verification, hardness testing, material certification, and documentation for all export consignments, ensuring complete compliance with customer requirements.

Engineering Support and Collaboration

Our experienced engineering team collaborates closely with customers from initial design concept through final production. We offer valuable design for manufacturability recommendations, rapid prototype development, technical problem-solving, and value engineering solutions to optimize component performance while improving manufacturing efficiency and reducing costs.

Quality Assurance and Testing Protocols

Every machined component at KPW undergoes comprehensive quality inspection using calibrated precision measuring instruments including CMM (Coordinate Measuring Machine), optical comparators, digital micrometers, bore gauges, and specialized fixtures. Our multi-stage quality control process includes in-process inspection where operators perform dimensional checks during machining operations, ensuring conformance before proceeding to subsequent operations.

Final inspection procedures involve 100% visual inspection for surface defects and statistical sampling for dimensional verification against approved engineering drawings. We conduct hardness testing, material composition verification, and when required, arrange for third-party metallurgical testing and material certification to meet customer specifications and industry standards.

Complete inspection reports, material test certificates, dimensional data, and traceability documentation accompany all shipments, providing customers with full confidence in component quality and compliance.

Industries and Applications We Serve

Automotive Manufacturing

As suppliers of precision CNC machined parts in India to the automotive industry, we manufacture critical transmission components, engine parts, suspension elements, braking system components, and steering assemblies that meet automotive industry quality standards for durability, performance, and safety.

Construction and Material Handling Equipment

Heavy equipment manufacturers rely on our machined components for excavators, loaders, concrete pumps, cranes, and material handling systems. We understand the demanding environments and heavy loads these machines operate under and engineer parts with appropriate strength, durability, and precision.

Oil and Gas Industry

Our machined connectors, flanges, valve components, and specialized fittings for the oil and gas sector meet stringent safety requirements, pressure ratings, and performance standards. We maintain complete material traceability and provide necessary certifications and documentation for critical applications.

General Engineering and Industrial Machinery

From industrial processing equipment to agricultural machinery, power transmission systems to custom automation equipment, our versatile machining capabilities serve diverse engineering applications requiring custom components manufactured to precise specifications.